Polyimide Tubing

Polyimide is a polymer thermoset plastic that has exceptional thermal stability, chemical resistance, and tensile strength. These characteristics make polyimide an ideal material for high-performance medical applications. The tubing is lightweight, flexible, and resistant to heat and chemical interaction.

Typical Applications

- Cardiovascular catheters

- Urological retrieval devices

- Neurovascular applications

- Fiber optics

- Intravascular drug delivery

- Balloon angioplasty & stent delivery systems

Polyimide Features

- Superior pushability & tractability

- Flexibility & kink resistance

- Column strength

- Ultra-smooth surface & transparency

- Chemically inert

- Torque transmission

- Gamma, EtO & E-beam sterilization tolerant

- Color selection

- USP Class VI Compliance

Standard Size/Tolerances

- Standard ID sizes from 0.004″ to 0.086″ (0.10mm to 2.18mm)

- Wall thickness from 0.0005″ to 0.008″ (0.0127mm to 0.2032mm)

ID Size/Tolerances

ID > 0.0200″ (0.51 mm) Tolerance: ± 1% of Nominal

ID < 0.0200″ Tolerance: ± 0.0002″ (0.005 mm) of Nominal

Wall Thickness/Tolerances

Wall > 0.0010″ (0.025 mm)

Tolerance: ±0.00025″ (0.006 mm)

Wall < 0.0010″

Tolerance: +0.00025″, – 0″

Material Property Information

Thermal Rating @ 20,000 Hours: 220°C Minimum (428°F)

Thermal Endurance: 400°C Minimum (752°F)

Tensile Strength: 20,000 PSI Minimum

Hoop Stress: 11,000 PSI Minimum

Burst Strength: (Hoop Stress x Wall Thickness)/OD Radius

Chemical Resistance: Excellent, most solvents/solutions

Radiation Resistance: 3.0 X 109 Gamma Dose rd

Coefficient of Thermal Conductivity: 35.0 X 10-5 Cal/sec/cm2/°C/cm

Coefficient of Thermal Expansion: 4.0 X 10-5/°C

Elongation @ Break: 50% Nominal

Dielectric Strength: 4,000 Volts/0.001″ Minimum

Dielectric Constant: 3.4

Melting Point: Nonexistent

Density @ Room Temp: 1.41 g/cc

Coefficient of Friction: 0.5

MicroCut Trimming Services

Replace in-house trimming operations and reduce lead time with our automated trimming service. Our MicroCut trim process provides:

- Precise, custom short lengths with square ends

- Trim capabilities as short as 0.0100″ (0.25 mm)

- Tolerances of +/- 0.005″ (0.13mm) to +/- 0.15% of length

- Minimal profile distortion and end flash

- MicroView diagnostic capabilities.

View available customizations and dimensions.

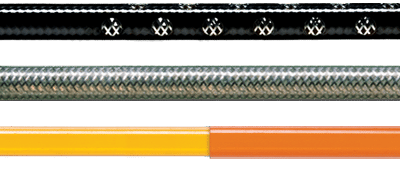

Polyimide

Reinforced

PTFE / Composite

Laser Machined