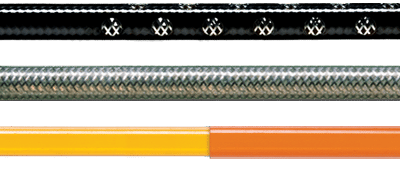

Reinforced Tubing

MicroLumen offers custom braid and coil reinforced tubing. Primary advantages of using reinforced tubing include increased column strength, torque transmission and increased burst strength. Reinforced tubes are available in a wide range of diameters and configurations. The construction of a typical reinforced tube consists of a substrate layer, a braided or coiled layer, and an exterior layer. Substrates can include Polyimide, PTFE liners and many thermoplastics like Pebax or Nylon. PTFE liners on the ID of the tube offer reduced surface friction and various materials, like Polyimide, Pebax, Nylon and Urethanes, can be applied to the OD for varying durometer and color.

Reinforced Tubing Specifications

- The most common braid/coil material is 304V stainless steel.

- Both round and flat wires are available. Common wire sizes:

- Round wire 0.0010″ to 0.004″

- Flat wire 0.0005″ x 0.0025″ and larger

- “PIC” count = per inch crosses (Braid)

- “WPI” count = wraps per inch (Coil)

- Higher PIC counts improve flexibility, while a lower PIC count increases longitudinal stiffness

- The PIC count can be varied within a specific length to provide variable flexibility. This can also be achieved via selective laser removal of OD layers or variable durometer reflows.

- Selective laser removal of Polyimide top-layers increases flexibility and helps in secondary processes & assembly

- Axial reinforcement provides added tensile strength and minimized elongation

View available customizations and dimensions.

Polyimide

Reinforced

PTFE / Composite

Laser Machined